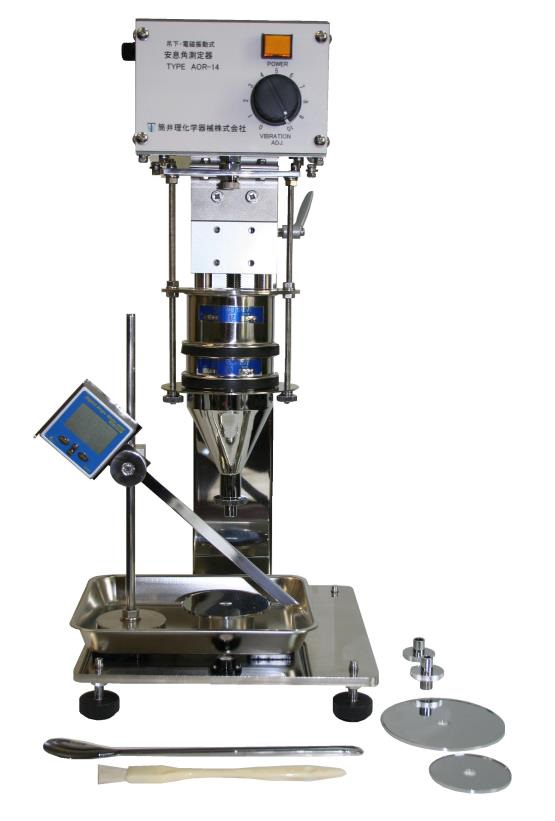

JV 1000 / JV 2000 粉體振實密度測定儀 JV 1000 / JV 2000

JV 1000 / JV 2000

粉體振實密度測定儀 JV 1000 / JV 2000

Tapped Density Tester / Bulk Density JV 1000 JV 2000

廠牌:代理

供應商:大台北尖端儀器有限公司

聯絡電話:02-2531-0981

| 快速詢價 |

JV系列振實密度計完全依照美國藥典第616章方法2和歐洲藥典2.9.15的標準設計,測量粉末、顆粒及類似樣品的振實密度。

這項技術特別應用在粉體流動性研究及最優化的運輸包裝的成本核算,如洗衣粉顆粒。

振實密度通過機械振實裝有樣品的帶刻度的量筒來計算(即抬升量桶並且讓它在自身重量下落特定的距離)

兩款測量儀JV1000、JV2000

JV1000和JV2000分別是單站和雙站振實密度計,用戶根據測量需求選擇,兩款儀器標配都採用250ml量筒,也可以選擇100ml或者更小的量筒及其對應儀器平台。

為了設定振實次數或時間,兩款儀器都配備有薄膜控制板,並且配有一個液晶螢幕方便設定實驗參數和控制測試過程。

流動性範圍

壓縮性

指數(%) 流動特性 Hausner Ratio(HR)

<10 優異 1.00-1.11

11-15 好 1.12-1.18

16-20 不錯 1.19-1.25

21-25 一般 1.26-1.34

26-31 差 1.35-1.45

32-37 很差 1.46-1.59

>38 非常非常差 >1.60

型錄號碼 描述

1601 JV 1000型單站振實密度計 (單量筒)

1602 JV 2000型雙站振實密度計 (雙量筒)

1603 IQ/QQ/PQ 認證文件

1604 250ml量筒(額外的)

1605 100ml量筒(選配)

1605A 100ml量筒專用平台 (選配)

1606 消音櫃

操作模式

JV 1000型和JV 2000型的操作模式相同。

稱出粗稱的樣本到100克±0.1%,放入帶刻度的量筒並標記未振實的體積。用標配卡件將量筒固定在測試儀的檢測平台。

除非特殊規定,一般設定振實次數為500次,然後操作儀器把振實後的體積記下來。重複振實操作,設定振實次數到750次;繼續重複測試並增加振實次數至1250次,直到振實後體積誤差少於2%。記錄最終的讀數。

將樣本重量除以最終振實體積得到振實密度,以g/ml為單位。

粉體的流動能力和壓縮性的測量可以由Hausner Ratio豪斯納比(振實密度/堆積密度)和壓縮性指數(振實密度-堆積密度/堆積密度x100)獲得。

對於自由流動的粉末,顆粒間的相互作用比較弱,所以未振實密度接近於振實密度。對於流動性差的粉末,結果恰恰相反。它符合Hausner Ratio豪斯納比越接近於1,流動性就越好的規律。通常流動性差的粉體,比率都大於1.25。特殊的消音櫃能把噪音從80分貝減低到58分貝。振實密度儀尺寸:280 mm(W)x250 mm(D)x670 mm(H)。

TAPPED DENSITY TESTERS SERIES JV

The Tapped Density Testers Series JV have been designed to measure the tapped density of powders, granules and similar products in accordance with USP Chapter <616> Method 2 and EP Chapter 2.9.15.

This technique is particularly useful in powder flowability studies and also in determining the amount of settlement during transit to optimize pack sizes e.g. washing powders.

Tapped density is achieved by mechanically tapping a measuring cylinder (i.e. raising the cylinder and allowing it to drop a specified distance under its own weight) containing the sample under test.

Two versions of the tester (JV 1000 and JV 2000) are available dependent on the number of test stations required (1 or 2). Both versions utilise 250 mL measuring cylinders as standard, however 100mL cylinders together with appropriate platforms are also available if required.

Both of the instruments concerned are equipped with membrane keypads for setting the number of strokes or time and an LCD screen to set the appropriate parameters and monitor the progress of the test.

MODE OF OPERATION

The mode of operation is identical on both models.

Weigh out a predetermined amount of the sample, say 100 g +/- 0.1%, place it in the graduated cylinder provided and note the unsettled volume. Secure the graduated cylinder to the test platform of the tester using the bayonet fitting provided for this purpose.

Unless otherwise specified, set the number of taps via the membrane keypad on the front of the instrument to 500 and operate the device making a note of the resulting tapped volume. Repeat this operation for a further 750 taps noting the volume once again. Continue repeating the test in increments of 1250 taps until the difference in tapped volume is less than 2%. Note the final reading.

The tapped density in grams per mL can now be calculated by dividing the sample weight by the final tapped volume.

Measures of the ability of the powder to flow and its compressibility can now be given in the form of the Hausner ratio (Tapped Density/Bulk Density) and the Compressibility Index ((Tapped Density – Bulk Density/Tapped Density) x 100).

In a free flowing powder, inter-particulate interaction is less significant and unsettled and tapped densities will be closer in value. In poorly flowing powders, the inverse is to be expected. It follows that the closer the Hausner ratio is to 1, the better the flow. Powders with poor flow generally have a ratio of greater than 1.25.

A special acoustic cabinet is available on request. The tapped density testers measure 280 mm (W) x 250 mm (D) x 670 mm (H).