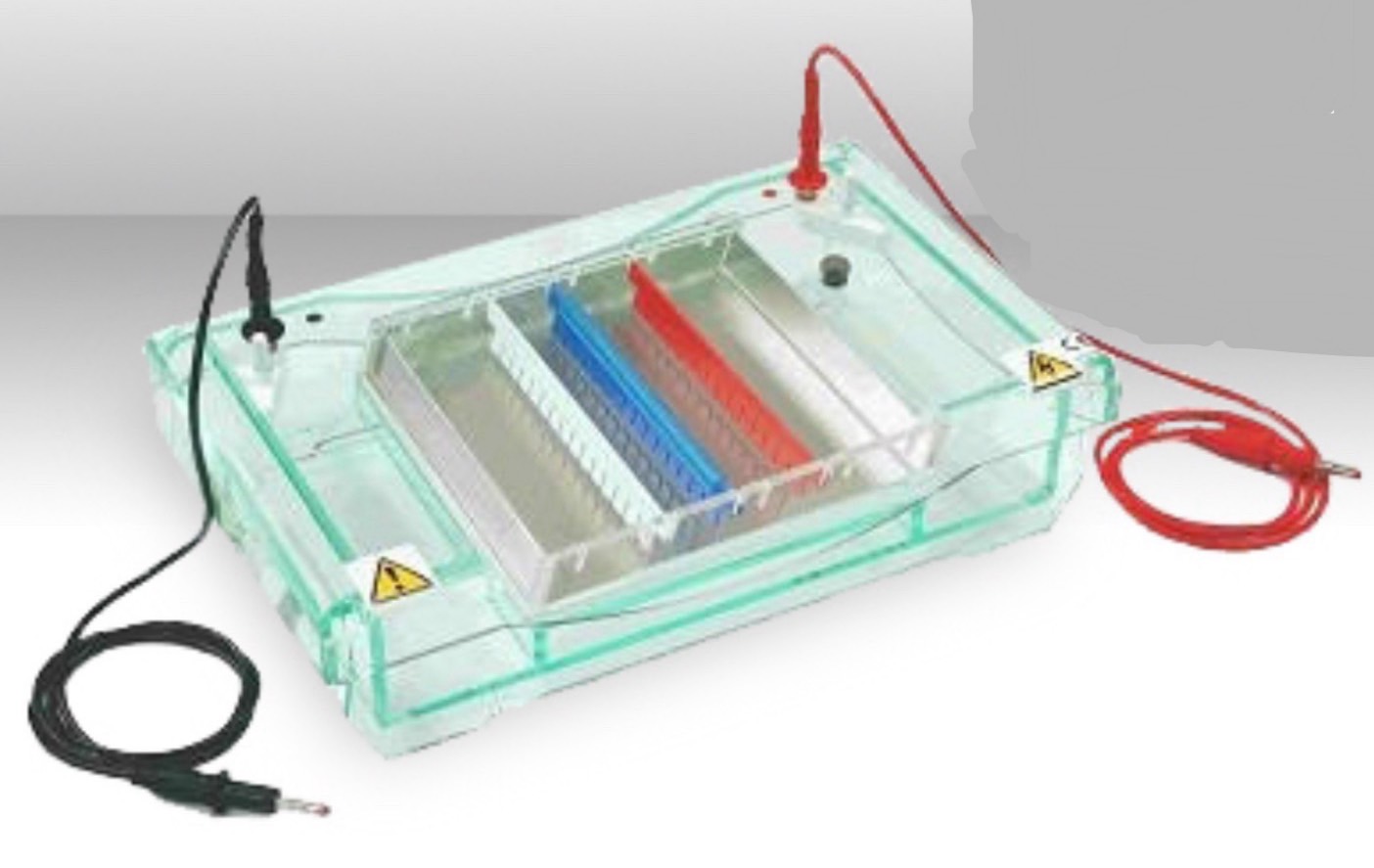

MCS 迷你型二氧化氯消毒裝置 (MCS)

MCS

迷你型二氧化氯消毒裝置 (MCS)

Mini chlorine Dioxide System (MCS)

廠牌:DRS 美國

供應商:智勤企業有限公司(超低溫冷凍櫃/生物安全櫃/離心機/滅菌鍋/CO2,O2培養箱/化學工作台)

聯絡電話:02-23955078 07-3451553

相關網頁

| 快速詢價 |

The FULLY AUTOMATED Mini-Chlorine Dioxide System (MCS) (patent pending) is the safest and one of the fastest devices currently available for the decontamination of biological safety cabinets. The MCS saves time and money, and eliminates the use of a carcinogen (formaldehyde). The MCS uses chlorine dioxide (CD) gas, the only alternative to formaldehyde validated by NSF International, the organization that establishes manufacturing and usage practices for biological safety cabinets. Built into the MCS is a charcoal gas-scrubbing unit, allowing trained technicians to safely remove chlorine dioxide gas from the target device after decontamination, requiring no external venting or chemical neutralization.

The MCS is compatible with ALL classifications, types and models of Biological Safety Cabinets

This includes: Class I’s, Class II Type A1, A2, B1, B2 and Class III’s. The MCS treats volumes up to 120 ft2 (3.4m3), more than sufficient for these and many other types of containment devices.

The MCS provides complete decontamination services in less than 4 hours, including the setup and tear down of the BSC. This is a very large improvement from formaldehyde, where the entire decontamination process encompasses almost 2 work days.

As a result of validation studies performed under the guidance of the NSF International CD gas is the only decontamination chemical alternative to formaldehyde included within their biological safety cabinet document as a validated decontamination method.

Why Decontaminate BSC’s?

Class I or Class II (laminar flow) biological safety cabinets are designed to minimize hazards inherent in work with biological agents. BSC’s can be used for work with biological agents assigned to biosafety levels 1 through 4, depending on the facility design as described in the CDC/NIH publicationBiosafety in Microbiological and Biomedical Laboratories. A BSC is a ventilated device for personnel, product, and environmental protection having an open front with inward airflow for personnel protection, downward HEPA filtered laminar airflow for product protection, and HEPA filtered exhausted air for environmental protection.

Recommendations and requirements to certify BSC’s come from a variety of sources. All manufacturers and NSF International recommend field certification of BSC’s. The Center for Disease Control (CDC) and NIH state that it is essential that Class I, II and III BSC’s be tested and certified.

Decontamination is a key component of certification.

NSF is responsible for developing and issuing protocols for BSC decontaminations, which are published in conjunction with CDC.

When are BSC Decontaminations Required?

- Decontamination shall be performed when maintenance work, filter changes, or performance tests require access to any contaminated portion of the BSC

- Decontamination shall be performed prior to relocation

- Decontamination shall be performed prior to decommissioning, disposal or salvage

- Decontamination may be performed after gross spills of biological agents

- Decontamination may be performed if a product contamination is linked to the BSC

- Decontamination may be performed prior to initiating a totally different work program, production run or study and shall be performed at the completion of a work program, production run or study

MCS advantages over formaldehyde

- The eradication rate of CD is significantly greater than that of formaldehyde, reducing contact time from at least 12 hours to less than 2 hours.

- The CD process does not leave a residue. This considerably reduces labor requirements following the typical formaldehyde decontamination.

- The cycle time for a decontamination, from sealing to reopening the containment device, is reduced from over 17 hours to less than 3 ½ hours. This allows the possibility of decontaminations to be performed in the morning, with servicing completed the same afternoon, eliminating a second trip to the site.

- Formaldehyde is a carcinogen. Chlorine Dioxide is not.

Packaging for the field service technician

- The MCS is packaged in a single case in which all items can be stored. This includes attachments, tools, tapes and all support supplies.

- The case has an extendable handle and rolling casters. The rotationally-molded wheeled case is manufactured from durable polyethylene with a full-length heavy-duty piano hinge, cable lid stays, military-style recessed latches and spring-loaded handles, tongue-in-groove aluminum valances, and padlock provisions if let on a site overnight.

- Universal intake / exhaust sealing panels, supply / return ducting lines, port / round duct adapters and a humidifier are supplied for all styles of BSC’s.

Essence of the MCS for the field service technician

- A humidity source, humidity meter, and biological indicator (optional) are the only items placed within the BSC to be decontaminated.

- The BSC is then sealed, incorporating into the seal a gas inlet and outlet port for use with the MCS.

- No other tubes, wires or other need to be run into the BSC.

- After appropriate humidity has been achieved, CD-producing and neutralization chemicals are added to the MCS, and the decontamination cycle begins.

- After an exposure with a duration of 85 minutes, CD gas is removed from the BSC using the scrubbing cycle of the MCS.

- After approximately 35 minutes, the MCS is disengaged from the BSC and the BSC may be unsealed.

Advantages of the MCS for the field service technician

- The MCS recirculates humidity and the decontamination gas through the BSC with or without the aid of the BSC’s internal air circulation blower(s). For the Class II type B2 the MCS is the circulation source for the entire decontamination process.

- The MCS circulates humidity and the decontamination gas through the BSC upstream and downstream exhaust HEPA filter plenum’s, eliminating the “dead leg” BSC problem, with or without the aid of the BSC’s internal air circulation blower.

- Gas tight sealing panels for the introduction of the decontaminating gas include a port that feeds through a power cord to energize a humidity generator within the BSC.

連結原廠

http://drslaboratories.com/products/mini-chlorine-dioxide-system-mcs/