TDA 熱膨脹分析儀器

TDA

熱膨脹分析儀器

Thermodilatometric Analysis

廠牌:ORTON/U.S.A.

供應商:建成科學儀器股份有限公司

聯絡電話:02-29103818

| 快速詢價 |

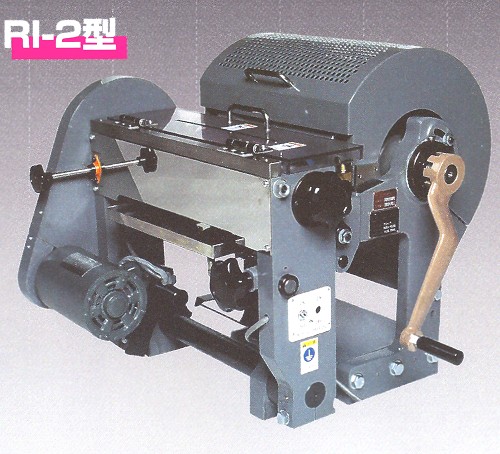

標準型橫臥式熱膨脹分析儀 / Standard, Single Sample, Horizontal Dilatometers

Thermal Dilatometric Analysis (TDA), often called "dilatometry", measures the dimensional change of a material (ceramics, glasses, metals, composites, carbon/graphite, minerals, polymers, and others) as a function of temperature. This test determines both reversible and irreversible changes in length (expansion and shrinkage) during heating and cooling, and pinpoints where reactions occur that cause expansion or contraction. Samples are quickly and easily measured for determining firing ranges and firing schedules, measuring thermal expansion ranges for glaze fits, and measuring thermal expansion ranges for R&D, QC or product certification. Orton dilatometers are used for ASTM E-228 testing.

A. Characteristics or Properties Measured

Coefficient of Thermal Expansion (CTE), softening point, glass transition temperature, curie point, crystalline transformation, phase transition, shrinkage, warping, bloating, sintering rate, isothermal creep, stress relaxation.

The test results are a graph of the TDA signal (converted to percent length change) on the Y-axis plotted versus the sample temperature in °C on the X-axis. Sample graphs of enhanced output are shown below.

下載本目錄文件請使用電子文件程式 PDF

The Dilatometer Brochure PDF format (429 kb).

| 機 器 型 號 | DIL 2010 B | DIL 2010 C | DIL 2010 STD | DIL 2012 STD | DIL 2016 STD | |

|---|---|---|---|---|---|---|

| . | . |

|||||

| Temperature Range | RT to 1,000°C |

RT to 1,000°C or -170°C to +300°C |

RT to 1,000°C |

RT to 1,200°C |

RT to 1,600°C | |

| Furnace | Kanthal |

Nichrome - Split Shell Cryogenic Chamber |

Kanthal |

Kanthal |

Silicon Carbide | |

| Thermocouple | Type "N" |

Type "S" |

||||

| Sample Holder & Probe Rod | Fused Quartz |

High Alumina | ||||

| Contact Load | 113 grams |

adjustable (4 grams min) | ||||

| Controlled Atmosphere Option | Not Available |

Yes |

Yes |

Yes |

Yes | |

| Power Requirments | 120 VAC, 15 amp, 50/60 Hz |

240VAC, 205 amp, 60/60 Hz |

||||

| Sample Size1 | 50 mm long X 20 mm diameter | |||||

| Temperature Control | Orton multi-segment Controller | |||||

| Data Aquisition | Orton On-Board Computer | |||||

| Data Analysis | Orton Analysis Software2 | |||||

| Computer Interface | RS232 Cable | |||||

| Warranty and Service | Warranty Info | |||||

Computer AnalysisEvery Orton dilatometer is supplied with the software to add to the user's PC in order to acquire, save and analyze the data generated by the dilatometer. The Orton Dilatometer Software is a Visual Basic executable routine written for Windows 95/98/2000/XP English language based personal computers. It can be used to monitor the dilatometer test in real time, or can be used to examine the test data after the run. The software imports the data through the RS232 interface, and stores it on the hard drive for immediate or post-testing analysis. The software enables the user to: View the dilatometer data in a variety of presentations:• Percent linear change (PLC) vs. temperature Perform a variety of analyses:• Calculate the coefficient of thermal expansion (CTE) between specified temperatures, or a series of specified |

|

其他特殊用途膨脹分析儀

|

| Vertical Dilatometer For larger samples, such as structural clay bodies, a vertical dilatometer is used. The sample is placed into the furnace and the vertical probe rod is lowered to contact the sample (as shown in the photo at the right). The furnace is heated according to the pre-programmed thermal cycle. As the sample temperature changes, the sample expands, pushing up on the probe rod, or shrinks, pulling away from the probe rod. The probe rod is vertically suspended and counterweighted so that gravity keeps it in constant contact with the sample. The probe rod transmits the amount of sample movement to the electronic displacement sensor located overhead and outside the furnace. Orton also designs and manufactures other types of dilatometers, including vertical, multiple sample, metallurgical, quenching, laser, and special application systems. |