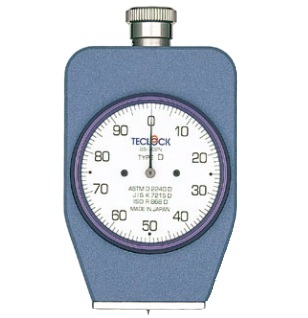

B, B-75, BB-75 韋伯斯特硬度計 B / B-75 / BB-75

B, B-75, BB-75

韋伯斯特硬度計 B / B-75 / BB-75

Webster Hardness Tester B , B-75 , BB-75

廠牌:代理

供應商:大台北尖端儀器有限公司

聯絡電話:02-2531-0981

| 快速詢價 |

|

規格

|

B 型

|

B-75 型

|

BB-75 型

|

|

適用範圍

|

鋁板、鋁管、鋁合金、銅板、銅管、銅合金、軟鋼板、軟鋼管等皆可測試.(操作簡單)

|

||

|

主要用於測量鋁合金材料,也可測量銅合金材料。

|

主要用於測量半硬狀態或全硬狀態的銅合金,測量退火狀態的不銹鋼等軟鋼,測量非常硬的鋁合金。

|

主要用於測量紫銅和退火黃銅等硬度較低的銅材料。

|

|

|

刻度範圍

|

0 - 20

|

||

|

測量範圍

|

鋁合金:24~110 HRE

|

銅合金 :15~90 HRF

|

HRE:18~100

|

|

鋁合金:83~113 HRE

|

|||

|

銅合金:60~90 HRF

|

|||

|

軟鋼 :20~100 HRB

|

|||

|

Webster Hardness Tester |

|

|

|

Models B, B-75, BB-75 |

|

Portable, fast, accurate hardness gauge available in several models for testing materials such as aluminum, brass, copper and mild steel. Quickly identify tempers. Tests a variety of shapes that other testers cannot check: Extrusions, Tubing and Flat Stock. |

|

|

|

|

Features |

|

The Model B Tester is designed to cover the hardness of aluminum alloys from the 1100 to the 7075 series. The 20 graduations on the Webster dial indicator covers the range between 25 and 110 on the Rockwell E Scale. The Model B-75 Tester was developed to obtain more sensitive response to slight changes in the upper range of hardness covered by the Model B. This sensitivity is particularly useful in testing mild steel and the stronger aluminum alloys. For brass the B-75 covers the range from annealed to full-hard. This added sensitivity is accomplished by incorporating a penetrator of slightly different contour and a heavier load spring than used in the Model B. The 20 graduations on the Webster dial indicator covers the range between 20 and 100 on the Rockwell B Scale. The Model BB-75 Tester was developed to answer the need of certain industries for a method of rapidly testing the hardness of electro-deposited copper and copper in the low hardness range. The B-75 penetrator is used to give sensitivity and the Model B load spring is employed to give light pressures. This combination allows the user to test the soft range of many common materials. |

|

Operation |

|

This sectional view shows the basic design principle of the Webster Hardness Tester. The different models vary only in penetrator and load spring design. These combinations give the ability to test a wide range of hardnesses and metals. The penetrator housing, which contains the penetrator and load spring, slides vertically in the frame of the tester when pressure is applied to the handles. Only sufficient pressure is needed to "bottom" the lower face of the housing against the work. Resistance of the work to the penetrator causes the penetrator to recede into the housing against the spring pressure. The degree of penetration on the test specimen is indicated on the dial indicator sitting on top of the housing assembly. The load can be varied by adjusting the nut above the load spring, permitting the dial reading to be easily corrected against a test block of known hardness. A penetration of .010 inch produces a full scale reading on the dial indicator. Therefore materials in the softer hardness range should be of sufficient thickness so that the anvil will not influence the test and produce an "anvil effect". In general, soft materials under .025 - .030 in thickness will not give true readings. |

|

Available Items |

|

|

|||

|

Item Number |

Item |

||

|

HA-5501 |

Model B Standard Webster Hardness Tester for use on material between 0.025" and 1/4" wall thickness. Comes equipped with a 3/8" Standard Diameter Anvil. Includes: instrument case, adjusting wrench, standard test strip, and spare penetrator. 25-110 Rockwell E Scale |

||

|

HA-5503 |

Model B-75, As Above (Brass) 20-100 Rockwell B Scale |

||

|

HA-5505 |

Model BB-75, As Above (Copper Low & Hard) |

||

|

HA-5511 |

Set:B |

Standard Test Strip - for everyday use in maintaining calibration of all Webster Hardness Tester models |

|

|

HA-5512 |

Set:B-75 |

||

|

HA-5513 |

Set:BB-75 |

||

|

HA-5514 |

VSet: B |

Verified Test Strip - confirmed to be within the hardness specified on the Test Strip label with a certified and traceable Bench Model Rockwell Hardness Tester. Each verified test strip is identified by a serial number and comes with a certificate, valid for one year , which testifies to the exact hardness of the test strip |

|

|

HA-5515 |

VSet:B-75 |

||

|

HA-5516 |

VSet:BB-75 |

||

|

OPTION# Add-On: |

|||

|

(Option 1) |

Reduced Diameter Anvil - 1/4", 3/16", or 1/8" (Note: Equip your tester with the largest diameter anvil possible for your intended job(s). This will help guard against flexing of the anvil and provide the firmest test action possible.) |

||

|

Increase the jaw capacity of the tester: OPTION#, Add-On: |

|||

|

(Option 2) |

Increase jaw capacity from 1/4" to 3/8" - add |

||

|

(Option 3) |

Increase jaw capacity between 1/4" and 1/2". Includes a 1" diameter spacer - add |

||

|

(Option 4) |

Increase jaw capacity between 3/8" and 3/4". Includes a 1-1/4" diameter spacer - add |

||

|

(Option 5) |

Increase jaw capacity between 1/2" and 7/8". Includes a 1", and a 1-3/4" diameter spacer - add |

||

|

(Option 6) |

5/8" to 1" Capacity - Increase jaw capacity between 5/8" and 1" Includes a 1", and a 1-3/4" diameter spacer - add |

||

|

|

|||