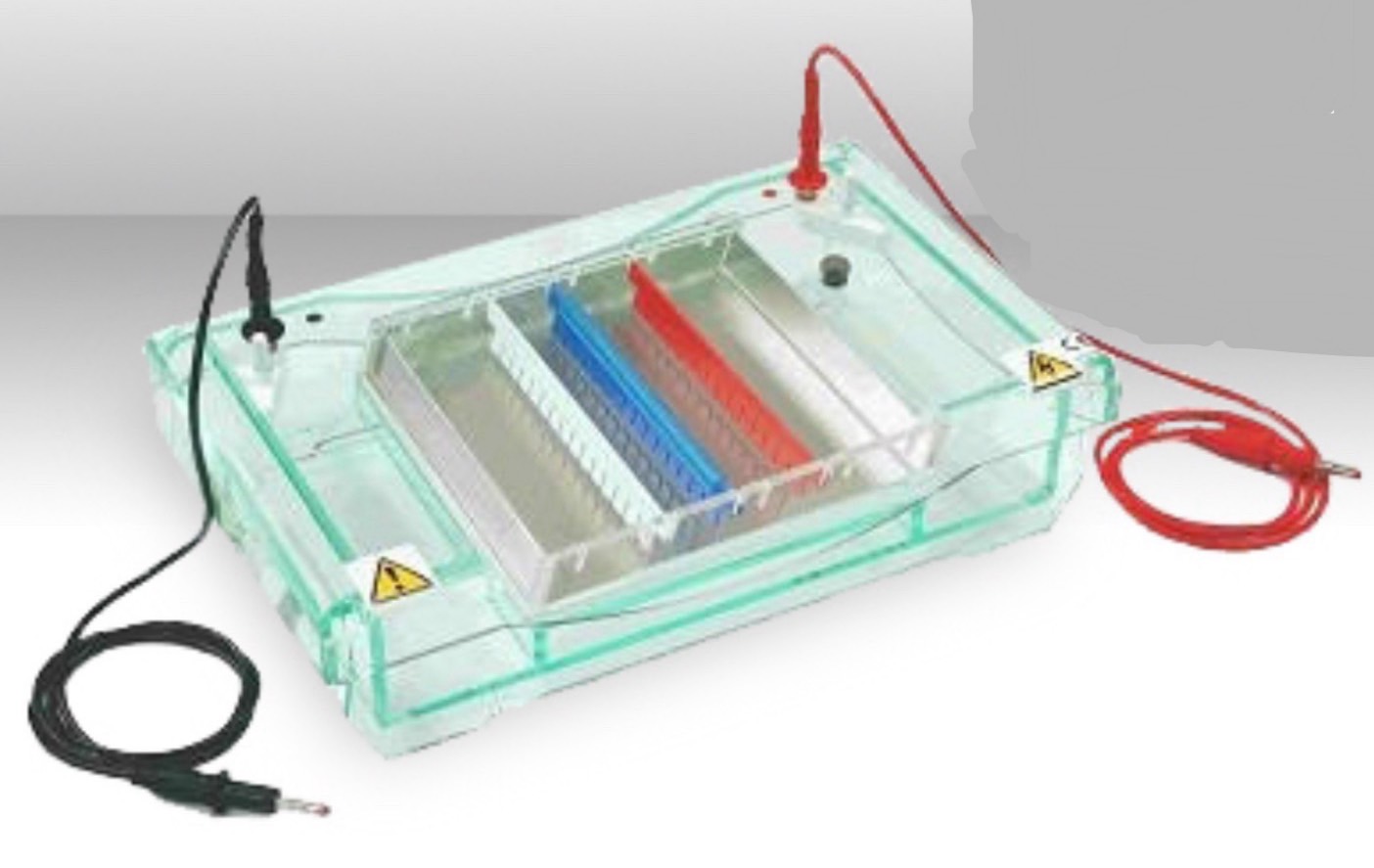

BOM-600DS 數位型真空乳化均質攪拌機

行動條碼QR Code

- 反應槽全容量:2.4L

- 轉速:100~12000 rpm

- 馬力:DC150W

- 特點:

4位數LED轉速顯示,數位定時功能0~9999分鐘設定。

扭力百分比區段顯示:(20、40、60、80、100%),並可扭力數位顯示,方便觀察黏度變化。

安全防護裝置:超負載回歸啟動裝置,過熱保護裝置,保險絲安全裝置。

低噪音結構設計,噪音值<68dB。

限制電流迴路裝置,超負載自動斷電,轉鈕重新啟動即可。

直流無碳刷馬達結構設計免保養,不會有碳刷粉末掉落污染樣品。

扭力補償自動定速功能。 - 保固期限二年

- Capacity:2.4L

- Speed: 100~12000rpm.

- Power:DC150W

- Digital LED display “RPM”、“Torque”、automatic speed integration to keep the steady speed, set in advance, even the fluid material is becoming more viscoid.

- Torque loading indication,20、40、60、80、100% .

- Overloading indication, current limitation and protection,

over heating protection feature. - Digital Timer Setting from 0~9999 minutes by easily

pressing button. - 1. Mixing oil and water phases materials in high speed to get perfect emulsion product of good quality.

2. With vacuum pump to take the air bubbles out of mixed product, and extend the time of storage.

3. Oue vacuum emulsifying equipment equipped with heating & cooling system which simplifies the processing. Within this same equipment, you can do from heating-melting-emulsifying-air bubble reduction

(by vacunm)-cooling without changing vessels, it saves lot of labor and time for your production.

4.Cream, Lotion, Lipstick, Shampoo, Ointment, Syrup, Injection, Mayonnaise, Dressing, Jam, Butter, Margarine, Polyester, Synthetic fiber, Paints, Synthetic resin paint, Color, Wax, Shoe cream, Coating liquid. - Two years warranty