EN ISO 9239-1 地板材熱幅射火焰傳播測試設備 EN ISO 9239-1

EN ISO 9239-1

地板材熱幅射火焰傳播測試設備 EN ISO 9239-1

Radiant Flooring Panel Apparatus EN ISO 9239-1

廠牌:代理

供應商:大台北尖端儀器有限公司

聯絡電話:02-2531-0981

| 快速詢價 |

輻射地面面板設備

EN ISO 9239-1

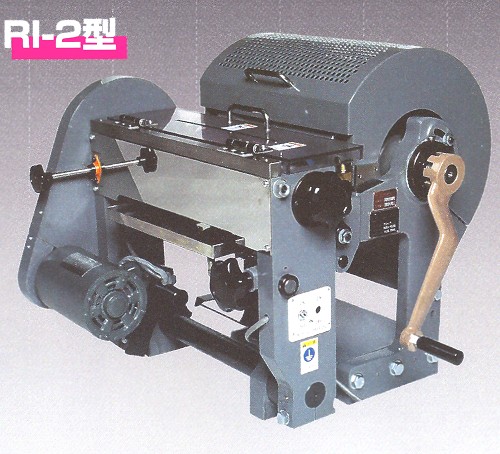

EN ISO 9239-1輻射地板面板測試是地板材料對Euroclass系統中的防火測試做出反應的基石,該測試使用輻射熱點火源在熱暴露下測量樣品火焰的擴散。暴露是指起源房間內發生的火災,該火災通過門的開口輻射到相鄰房間或走廊的地板上,與將地板材料分類為A2FL,BFL,CFL和DFL類別有關符合BS EN 13501-1 2007 + A1 2009中的要求.EN ISO 9239-1適用於地板,該設備還可用於根據標準ASTM E648和DIN 4102;第14部分進行測試。

測試室由覆蓋有拋光不銹鋼面板的支撐框架組成,測試室用矽酸鈣絕緣板絕緣,並設有耐溫觀察窗。不銹鋼樣品支架組件安裝在滑動平台上,以允許安全輕鬆地加載測試樣品。

控制系統調節流量以確保恆定的空氣混合氣,這對於在測試過程中保持恆定的熱通量曲線非常重要。陶瓷多孔輻射板配有質量流量儀表,可對氣體和空氣供應進行微調。安全儀表也包括在內。

規格與功能

• 試驗室和排氣系統(包括熱電偶)

• 帶有支架,校準的熱通量計和安裝件的虛擬校準標本

•滑動樣品架組件,可輕鬆安全地裝載樣品

• 燃氣多孔陶瓷輻射板組件

• 質量流量氣體控制器,可對面板上的氣體和空氣進行微調

• 校準的光學高溫計,可讀取輻射板的表面溫度(選件)

• 經過的計時器

• 白光衰減系統,用於煙霧密度測量,符合DIN 50055

• 丙烷引燃器組件

• 排氣罩和排風管道,帶風扇

• 數據收集系統,包括:

◦ 帶TFT監視器的個人計算機(配置為英語)

◦ 數據採集硬體和電纜

◦ 根據測試方法顯示和報告測試數據和測量值

◦ Microsoft Windows XP / Vista相容軟體

文件(全部為英文),包括:

◦ 合格證明

◦ 熱流量計校正證書

◦ 測溫儀校正證書

◦ 完整的操作手冊

技術數據和要求

電氣:120V AC 60Hz / 230V AC50Hz– 25A

尺寸:2400mm (W) x 2300mm x (H) x 700mm (D)

設備重量:400 kg

環境溫度:操作於在10°C至35°C

氣體供應:測試中首選的燃料氣體是空氣和丙烷的混合物

丙烷:流動需要能夠在最小壓力為3Bar最低純度95%的遞送1KG /小時

清潔和乾燥的空氣:流量必須能夠在7 Bar的額定壓力下以350nl / min的速度輸送,這是獲得火焰穩定性進行測試所必需的

Radiant Flooring Panel Apparatus

EN ISO 9239-1

The EN ISO 9239-1 Radiant Flooring Panel test is the cornerstone of the flooring materials reaction to fire tests in the Euroclass system. The test measures the spread of flame of the sample, under thermal exposure, using a radiant heat ignition source. The thermal exposure is that of a fire growing in the room of origin that through a door opening, radiates onto the floorings in an adjacent room or corridor. It is relevant to classification of the flooring material into classes A2FL, BFL, CFL and DFL as set out in BS EN 13501-1 2007 + A1 2009. EN ISO 9239-1 applies to floorings. The apparatus can also be used for tests to standards ASTM E648 and DIN 4102; Part 14.

The test chamber consists of a support frame covered with polished stainless steel panels. The resulting test chamber is insulated with calcium silicate insulation board and is provided with a temperature resistant observation window. The stainless steel sample support assembly is mounted on a sliding platform to allow safe and easy loading of the test sample.

A ceramic porous radiant panel complete with mass flow instrumentation with fine adjustment for the gas and air supplies. The control system regulates the flow rates to ensure a constant air gas mixture, which is very important in achieving a constant heat flux profile during the test. Safety instrumentation is also included.

Specification & Features

•Chamber and Exhaust system (thermocouples included)

•Dummy calibration specimen with holder, calibrated heat flux meter and mounting

•Sliding sample holder assembly for easy and safe loading of samples

•Gas fired porous ceramic radiant panel assembly

•Mass flow gas controllers with fine adjustment for the gas and air supply to the panel

•A calibrated Optical Pyrometer to read surface temperature of radiant panel(option)

•Elapsed timer

•White Light attenuation system for smoke density measurement, according to DIN 50055

•A propane pilot burner assembly

•Exhaust hood and extraction duct, complete with fan

•Data Acquisition System consisting of: ◦Personal computer with TFT monitor(configured for English)

◦Data Acquisition Hardware and cabling

◦Display and reporting of test data and measured values according to the test method

◦Microsoft Windows XP/Vista compatible software

•Documentation(all in the English language) consisting of: ◦Certificate of conformity

◦Calibration Certificate for Heat Flux meter

◦Calibration Certificate for Pyrometer

◦Full Operation Manual

Technical Data & Requirement

Electrical: 120V AC 60Hz / 230V AC50Hz– 25A

Dimensions: 2400mm (W) x 2300mm x (H) x 700mm (D)

Weight of equipment: 400 kg

Ambient Temperature: Operating 10°C to 35°C

Gas Supplies: The preferred fuel gas used in the test is a mixture of air & propane

Propane: The flow needs to be capable of delivering 1kg/hour at a minimum pressure of 3 Bar with a minimum purity of 95%

Clean & Dry Air: The flow needs to be capable of delivering 350nl/min at a nominal pressure of 7 Bar. This is required to obtain flame stability for testing

Water supply with drain or re-circulation system to cool the heat flux meter (1l/min)

Suitable exhaust system, de-coupled from the exhaust stack, whose air velocity should be 2.5+0.2m/s within the stack with the panel turned off, dummy specimen in place and access door closed. An axial flow fan with a variable extraction rate up to a maximum of 2500 m3/h is suitable